Industrial processes today are more complex, precise, and efficiency driven than ever before. From food production and chemical processing to wastewater management and manufacturing, industries depend on equipment that can handle challenging materials while maintaining consistent performance. One solution that has seen steadily rising demand is the PC pump. Known for its reliability and versatility, this type of pump has become essential in industries where accuracy, durability, and gentle handling of materials matter most.

Understanding What Makes PC Pumps Unique

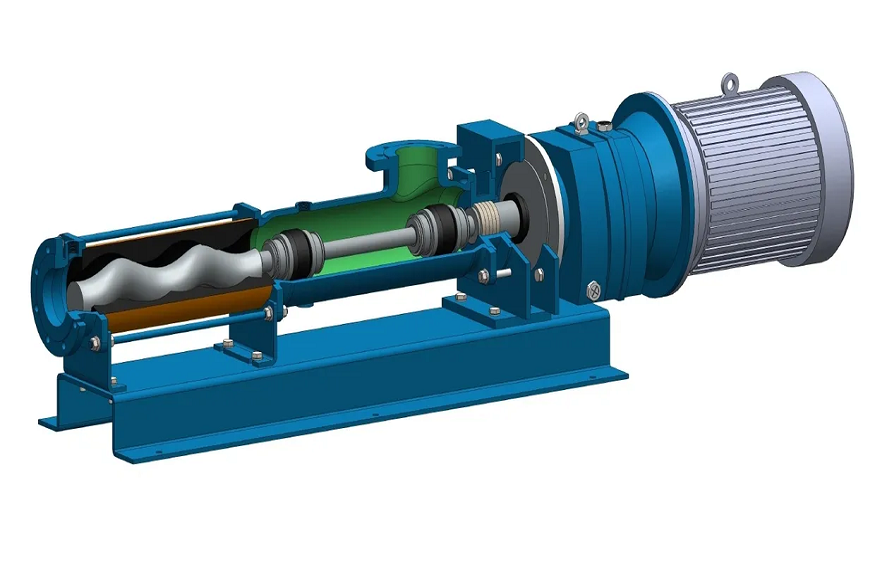

A PC pump, also known as a progressing cavity pump, operates using a rotating helical rotor inside a stator. This design creates sealed cavities that move fluid smoothly from the inlet to the outlet. Unlike pumps that rely on high speed impellers, this mechanism allows for controlled, low shear movement of materials.

This operating principle makes PC pumps especially valuable in industries that deal with viscous, abrasive, or sensitive substances. The ability to maintain a steady flow regardless of pressure changes is one of the key reasons their use has expanded across multiple sectors.

Industrial Growth and the Need for Reliable Flow Control

As industries scale up production, they require equipment that can deliver consistent results without frequent downtime. Many industrial fluids are difficult to move due to thickness, solids content, or sensitivity to agitation. Traditional pumping solutions may struggle under these conditions, leading to inefficiencies or product loss.

PC pumps address these challenges by providing predictable flow rates and stable operation. Their design allows industries to maintain precise control over processes, which is increasingly important in automated and high-volume environments.

Handling Viscous and Sensitive Materials

One of the standout advantages of PC pumps is their ability to handle viscous materials without compromising structure or quality. This capability is particularly valuable in food processing, pharmaceuticals, and specialty manufacturing.

For example, in food related applications, gentle handling is essential to preserve texture and consistency. Chocolate pumps are a common use case, as they must move thick, temperature sensitive material without introducing excessive shear or air. PC pumps are well suited for this task, making them a preferred choice in applications that require careful material handling.

Demands in the Food and Beverage Industry

The food and beverage sector has seen increased automation and stricter quality standards. Consistency, hygiene, and process control are critical. PC pumps support these demands by delivering smooth flow and minimizing product degradation.

From sauces and pastes to confectionery applications, these pumps help maintain uniformity throughout production. Their ability to handle both low and high viscosity materials with equal efficiency contributes to their growing adoption in food manufacturing environments.

Performance in Harsh and Abrasive Conditions

Beyond food processing, PC pumps are widely used in industries that handle abrasive or solid laden fluids. Mining, wastewater treatment, and chemical processing often involve materials that can cause rapid wear in less robust pumping systems.

The design of PC pumps allows them to manage these harsh conditions effectively. Their steady flow reduces turbulence, which in turn minimizes wear on components. This durability translates into longer service life and reduced maintenance requirements, making them a cost effective solution over time.

Supporting Precision in Industrial Processes

Modern industries increasingly rely on precision. Whether dosing chemicals, transferring materials between stages, or maintaining exact flow rates, accuracy is essential. PC pumps excel in metering and dosing applications due to their predictable output.

This precision supports better quality control and reduces waste. In industries where margins are tight and efficiency is critical, reliable flow control can significantly impact overall performance and profitability.

Energy Efficiency and Operational Stability

Energy efficiency has become a major consideration in industrial operations. Equipment that operates smoothly and consistently without excessive power demand helps organizations manage costs and meet sustainability goals.

PC pumps are valued for their ability to operate at low speeds while still delivering required flow rates. This reduces energy consumption and limits heat generation, which is particularly important when handling temperature sensitive materials. Stable operation also reduces the likelihood of system stress and unexpected failures.

Adaptability Across Multiple Industries

One of the reasons for the high demand of PC pumps is their adaptability. A single pump design concept can be applied across a wide range of industries with varying requirements. Adjustments in size, materials, and configuration allow PC pumps to meet specific application needs.

From handling thick slurries in industrial processing to delicate applications such as chocolate pumps in food production, this versatility makes PC pumps a preferred choice for engineers and facility managers alike.

Maintenance and Long Term Value

Industrial downtime is costly. Equipment that requires frequent repairs or replacements can disrupt operations and increase expenses. PC pumps are designed for ease of maintenance, with components that can often be serviced without full system disassembly.

This practical advantage adds to their long term value. While initial selection requires careful consideration of application needs, the operational reliability of PC pumps often results in lower total ownership costs compared to less suitable alternatives.

The Future of PC Pumps in Industry

As industries continue to evolve, the demand for flexible, efficient, and reliable pumping solutions will only increase. PC pumps are well positioned to meet these future challenges due to their proven performance across diverse applications.

Advances in materials, automation, and process control are likely to further enhance their capabilities. Whether supporting large scale industrial operations or specialized processes requiring gentle handling, PC pumps will remain a key component in modern industry.

The high demand for PC pumps reflects a broader shift toward precision, efficiency, and reliability in industrial systems. Their ability to handle everything from abrasive slurries to sensitive materials like those used in chocolate pumps highlights why they have become an essential solution across so many sectors.